4 way vs 2 way pallets: key differences, advantages, and practical uses for warehouses, distribution centers, and shipping operations.

When it comes to efficient material handling and warehouse logistics, choosing the right type of wood pallet is essential. Among the most common options in the industry are 4 way pallets (four-way pallets) and 2 way pallets (two-way pallets).. While both serve the same basic purpose—to support goods during storage and transportation—their design and functionality vary, directly impacting your operation’s efficiency and cost-effectiveness.

In this blog, we’ll break down the difference between 4 way pallets and 2 way pallets, highlight their advantages, discuss common industry use cases, and help you determine which is best for your business.

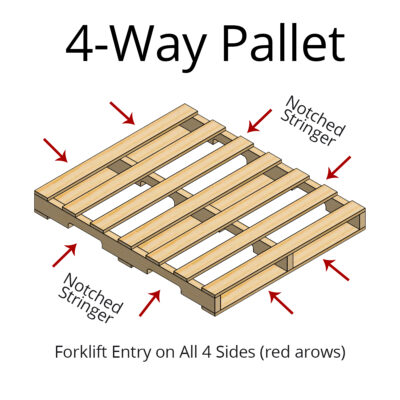

What is a 4 way Pallet?

A 4 way pallet, also called a four-way entry pallet, allows forklifts, pallet jacks, or a low profile 4 way pallet jack to enter from all four sides.. This access is made possible by the way the stringers or blocks are constructed and positioned underneath the wooden pallet deck.

Key Features:

- Entry on all four sides

- Typically block-style pallets or notched stringer pallets

- Easier to maneuver in tight spaces

- Commonly used in automated warehouses, international shipping, and retail distribution

- Standard 4 way pallet sizes include 48”×40”, commonly known as GMA pallets. Other typical sizes are 42”×42” and 48”×48”, while international standards include 1200×800 mm and 1200×1000 mm.

Benefits of 4 way Pallets:

- Greater versatility for loading and unloading

- Improves space utilization, and warehouse efficiency

- Ideal for operations with frequent handling or shifting

- Often preferred for export due to international shipping standards

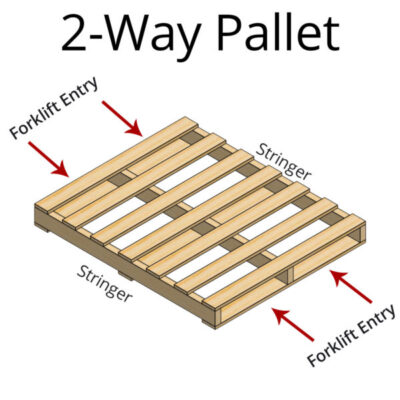

What is a 2 way Pallet?

A 2 way pallet, also called a two-way wooden pallet or 2 way stringer pallet, allows forklift or pallet jack entry from only two sides, usually the front and back. The other sides are blocked by solid stringers, making them strong and cost-effective but less maneuverable.

Key Features:

- Entry from two opposite sides only

- Often notched for limited access on the other two sides

- Common in traditional warehouse setups or closed-loop systems

- Standard 2 way pallet sizes include 48”×40” (GMA pallets), 42”×42”, and 48”×48”.

Benefits of 2 way Pallets:

- Generally, less expensive to manufacture

- Suitable for single-direction workflows

- Offers sufficient support for heavy static loads

- Typically used for long-term storage or internal operations

4 way vs. 2 way Pallets: Key Differences

| Feature | 4 way Pallet | 2 way Pallet |

| Forklift Access | All four sides | Two sides only |

| Maneuverability | High | Limited |

| Cost | Higher | Lower |

| Strength | Often higher due to block design | Strong but less flexible |

| Use Cases | Export, automated systems, high turnover, international shipping | Static storage, internal use, low mobility needs |

Which Wood Pallet Should You Choose?

The right wooden pallet choice depends on your industry, storage method, handling process, and transportation needs:

- Choose 4 way pallets if your operation requires frequent movement, tight warehouse spacing, or global shipping. They are especially beneficial in automated warehouses or distribution centers.

- Opt for 2 way pallets if you need a cost-effective solution for static loads or in-house processes, such as manufacturing plants or internal storage facilities.

For example, in a fast-paced distribution center, the maneuverability of 4 way pallets can significantly reduce handling time. On the other hand, if you’re running a closed-loop manufacturing system, 2 way pallets might meet your needs just fine.

Final Thoughts

Understanding the difference between 2 way and 4 way pallets is critical for making informed decisions in warehouse logistics and material handling. Whether you’re trying to optimize space, reduce handling time, or save on costs, the type of wooden pallet you use plays a big role in your overall supply chain efficiency.

Still unsure which pallet type is best for your operation? We offer 4 way pallets for sale and 2 way pallets for sale at competitive prices. Fill out our Request A Quote (RAQ) form—we’ll help you find the right pallet for your business needs.

Frequently Asked Questions (FAQ)

Q: What is the difference between 4 way and 2 way pallets?

A: The main difference is forklift and pallet jack access. Four-way pallets allow entry from all sides, while two-way pallets allow entry from only two sides.

Q: Are 4 way pallets stronger than 2 way pallets?

A: 4 way block pallets or notched stringer pallets tend to be more versatile and better for heavy-duty handling, while 2 way pallets are strong for static loads but less flexible.

Q: Why are 4 way pallets better for shipping?

A: They reduce handling time, improve warehouse space utilization, and comply with international shipping standards.

Q: Are 2 way pallets cheaper?

A: Yes. They are simpler to manufacture and ideal for internal or closed-loop operations where high maneuverability isn’t needed.

Q: What is a low profile 4 way pallet jack?

A: A low profile 4 way pallet jack is a specialized material handling tool designed to lift and maneuver four-way entry pallets. The term “low profile” refers to the jack’s lowered fork height, typically around 1.75 inches, allowing it to access pallets with minimal clearance—often as low as 2 inches. This feature is particularly beneficial in tight warehouse layouts or when handling low-clearance pallets, enabling efficient movement in constrained spaces. These pallet jacks are commonly used in operations where maximizing storage density and accessibility is crucial.