When businesses compare block pallets vs. stringer pallets, the conversation usually comes down to three main factors: cost, durability, and operational efficiency. While both pallet types serve important roles in the supply chain, stringer pallets remain the most widely used wood pallet in North America — and for good reason.

They are versatile, lightweight, customizable, and cost-effective. For most domestic shipping and warehousing operations, stringer pallets deliver the best balance of performance and value.

Let’s break down the differences, explore the components of each pallet type, and help you determine which option is the right fit for your operation.

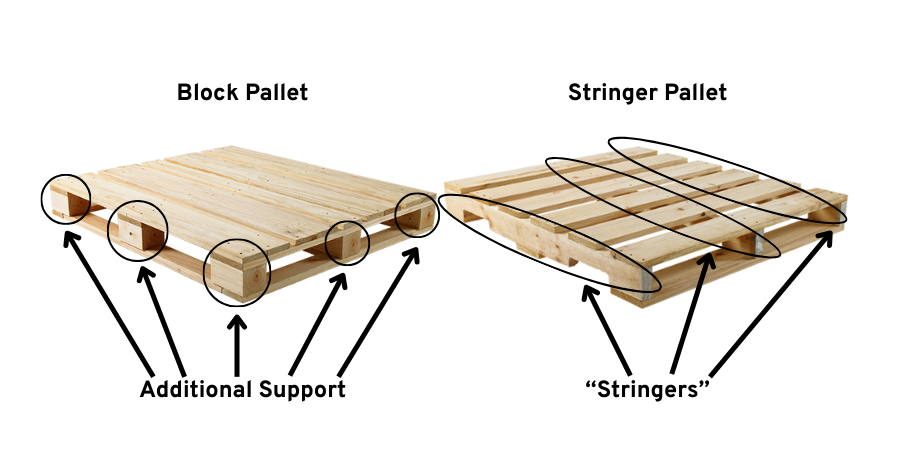

What is a Stringer Pallet?

A stringer pallet is constructed using three long, parallel boards called stringers that run lengthwise between the top and bottom deck boards. These stringers provide structural support and help distribute weight evenly across the pallet.

Traditional stringer pallets allow for two-way forklift entry, meaning forklifts can access them from the front and back. However, many stringer pallets can be notched, allowing for partial four-way forklift access — increasing versatility without significantly increasing cost.

Because of their straightforward design, stringer pallets are commonly used in:

- Domestic freight shipping

- Warehousing and storage

- Retail distribution

- Manufacturing operations

- Food and beverage logistics

They are often considered the “workhorse” of the U.S. pallet industry.

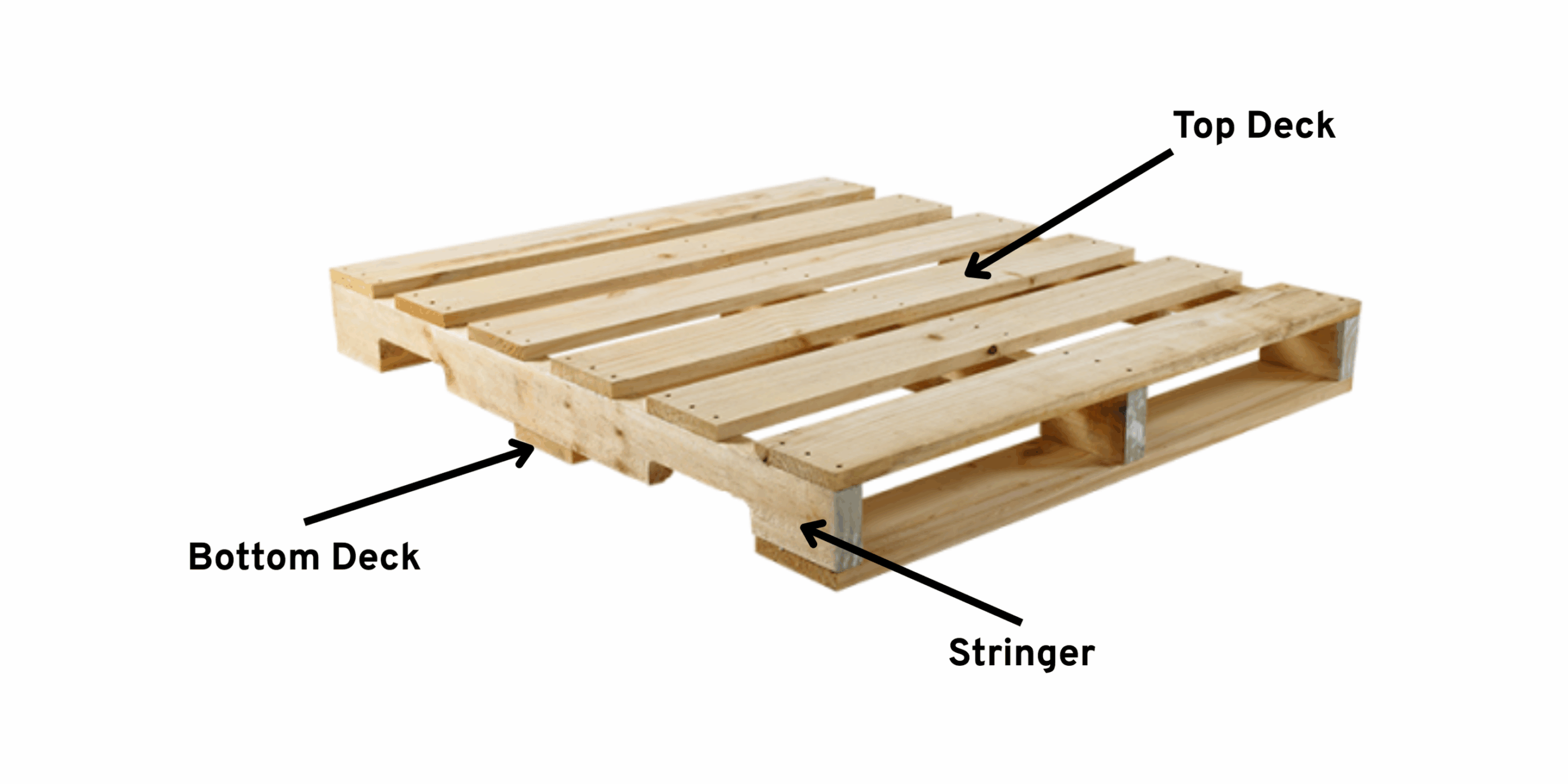

Parts of a Stringer Pallet

Understanding pallet components helps clarify why stringer pallets are so widely adopted:

- Top Deck Boards – The horizontal boards that create the load-bearing surface.

- Stringers – Three long boards that provide structural support.

- Bottom Deck Boards – Boards on the underside that add stability and stackability.

- Fasteners – Nails or staples that secure all components together.

Because there are fewer components compared to block pallets, repairs are typically quicker and more cost-effective.

What is a Block Pallet?

A block pallet uses solid wood blocks — typically nine — positioned at each corner and center point of the pallet. These blocks connect the top and bottom deck boards and allow for true four-way forklift entry, meaning forklifts and pallet jacks can lift the pallet from all four sides.

Block pallets are often used in:

- Heavy-duty industrial environments

- Export and international shipping

- Automated warehouse systems

- High-load capacity applications

Their design provides additional structural strength, but that added strength also increases material usage, weight, and cost.

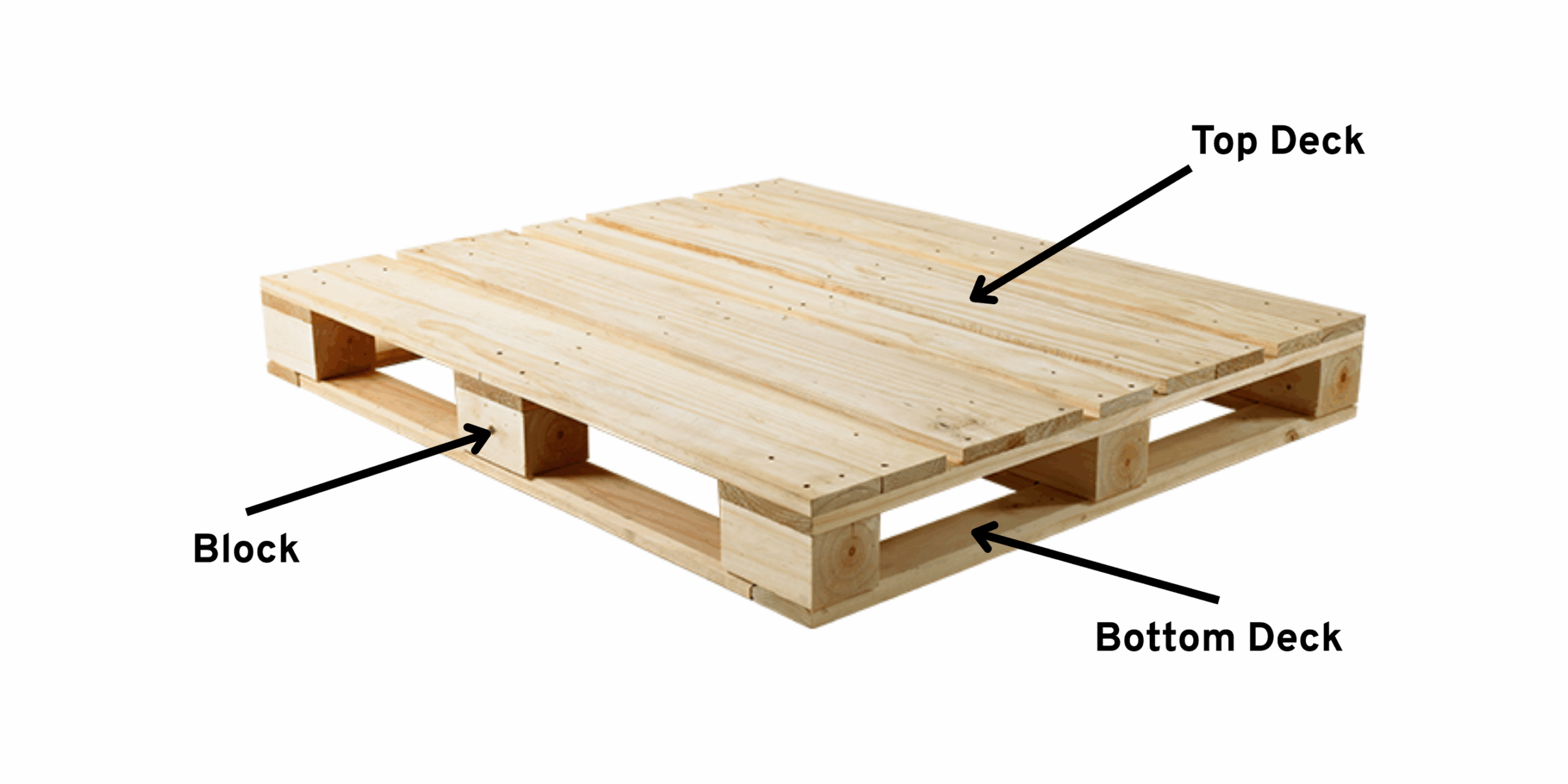

Parts of a Block Pallet

- Top Deck Boards – Surface area where goods are stacked.

- Bottom Deck Boards – Provide stability and structural balance.

- Blocks – Nine solid blocks forming the pallet’s foundation.

- Stringer Boards (or runners) – Short boards connecting blocks.

- Fasteners – Nails or staples securing the assembly.

Because block pallets contain more components, they generally require more labor and material to manufacture and repair.

Key Differences Between Block and Stringer Pallets

When comparing the two designs, here’s how they stack up:

| Feature | Stringer Pallet | Block Pallet |

| Entry Type | 2-way (notched = partial 4-way) | True 4-way entry |

| Weight | Lightweight | Heavier |

| Cost | More affordable | Higher upfront cost |

| Durability | Ideal for light to medium loads | Best for very heavy loads |

| Repairability | Easier and less expensive to repair | More complex repairs |

| Availability | Widely available in North America | Less common domestically |

| Common Use | Warehousing, domestic shipping | Export, heavy-duty industries |

For most businesses operating within North America, the additional cost and weight of block pallets often outweigh the benefits.

Why Stringer Pallets Are the Industry Standard in North America

- Cost-Effective Solution

Stringer pallets use fewer materials and require less labor to build. This translates into:

- Lower initial purchase price

- Lower repair costs

- Easier recycling or rebuilding

For companies managing large pallet inventories, these savings add up quickly.

- Lightweight and Efficient

Because stringer pallets are lighter, they:

- Reduce freight weight costs

- Improve fuel efficiency in transportation

- Make manual handling easier for warehouse staff

- Increase operational productivity

In industries where speed and throughput matter, every pound counts.

- Widely Available

Stringer pallets are the most commonly used wood pallet design in the United States. Their widespread adoption means:

- Faster sourcing

- Easier replacement

- Better compatibility with standard warehouse systems

Availability reduces downtime and keeps operations moving smoothly.

- Customizable Design Options

Stringer pallets can be built to meet a variety of specifications:

- Standard 48×40 pallets

- Custom sizes

- Notched stringers for partial 4-way entry

- Heat-treated pallets for export

- Heavy-duty reinforced builds

Customization ensures businesses get exactly what they need without paying for unnecessary features.

- Sustainability and Recycling

Sustainability is a growing priority across supply chains. Stringer pallets support environmental goals because they:

- Are easily repaired and reused

- Can be recycled into new pallets

- Can be ground into mulch, bedding, or biofuel

- Require fewer raw materials

Wood pallets remain one of the most recycled packaging products in the U.S., making them an environmentally responsible choice.

When Does a Block Pallet Make Sense?

While stringer pallets are ideal for most domestic operations, block pallets may be the right choice when:

- Loads are extremely heavy

- True four-way forklift entry is essential

- Automated systems require consistent entry from all sides

- International customers prefer block-style pallets

Block pallets can offer slightly greater durability in high-load environments, but many businesses find that properly built stringer pallets meet their needs without the added expense.

Frequently Asked Questions (FAQ)

Q: Are stringer pallets strong enough for industrial use?

Yes. Stringer pallets are engineered to handle most warehouse and transport loads. For light to medium-duty industrial applications, they perform exceptionally well.

Q: Why are stringer pallets cheaper than block pallets?

Their simpler design uses fewer materials and requires less labor to build. Repairs are also faster and more affordable.

Q: Can stringer pallets be used for international shipping?

Yes. As long as they are heat treated to meet ISPM-15 regulations, stringer pallets can be exported internationally.

Q: Do block pallets last longer?

Block pallets may offer slightly greater durability under extreme loads. However, properly maintained stringer pallets can be reused multiple times and repaired when necessary.

Q: Which pallet type is more sustainable?

Both pallet types are recyclable. However, stringer pallets are often easier to repair and reuse, reducing material waste and extending lifecycle value.

Final Thoughts: Choosing the Right Pallet for Your Operation

When comparing block pallets vs. stringer pallets, the decision ultimately depends on your specific operational needs. If you are shipping overseas or managing extremely heavy loads, block pallets may be worth considering.

However, for most domestic businesses focused on cost control, efficiency, and sustainability, stringer pallets remain the smarter, more practical choice. They provide dependable strength, lighter weight, easier repair options, and better overall value.

If you’re evaluating pallet options for your facility, we’re here to help. Fill out our Request A Quote (RAQ) form today, and our team will work with you to design the right pallet solution for your business needs. Let’s build a stronger, more efficient supply chain together.