Pallet mold is a common concern for manufacturers, warehouses, and distribution centers because mold spores exist naturally in the environment, and wood pallets provide an organic surface that supports fungal growth when moisture is present. While pallet mold does not typically weaken pallets immediately, it can contaminate products, disrupt quality programs, and reduce pallet usability. At Performance Pallet, we understand that pallets do more than move products; they protect them in industries where cleanliness, safety, and compliance matter. Proactive mold prevention is essential to safeguarding your product, your reputation, and your bottom line.

This is especially critical for food-grade pallets, such as our 48×40 wooden pallets, which must be heat-treated and undergo strict quality controls to prevent mold from contaminating food during transport.

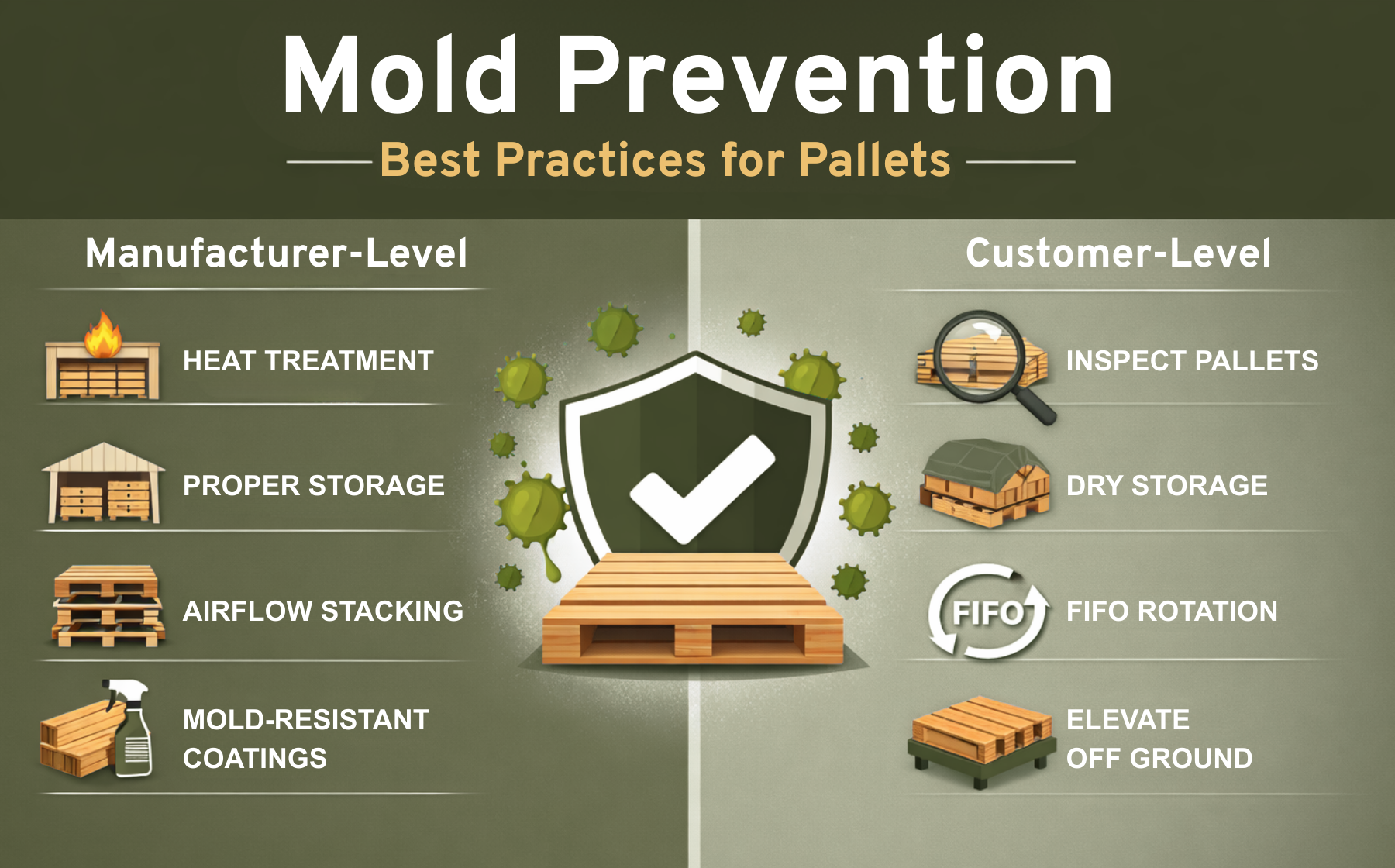

Both new and recycled wood pallets can develop mold when exposed to the right conditions. However, with proper manufacturing controls and responsible customer handling, mold risk can be reduced. Mold prevention is most effective when it is approached as a shared responsibility throughout the pallet’s lifecycle.

Here is how we help protect pallets from mold, from production to end use.

What Causes Mold on Wood Pallets

Mold develops when several environmental conditions align. Understanding these factors is the foundation of effective prevention.

- Moisture content above approximately nineteen percent, which research from Virginia Techs Center for Unit Load Design identifies as the threshold where mold can grow on wood

- Limited airflow, which allows moisture to remain on pallet surfaces

- Organic material that provides a natural food source for fungal growth

Manufacturer-Level Mold Prevention

The first opportunity to prevent mold starts at the manufacturing stage. How pallets are treated, stored, and handled directly impacts their resistance to mold growth.

Heat Treatment & ISPM-15 Compliance

Heat treatment under ISPM 15 standards is designed to kill insects and pests for export compliance, not to prevent mold. Heat treatment does not reliably reduce moisture content and can draw moisture and sugars to the wood surface, which may increase mold risk once exposed to humid environments.

Proper Stacking and Handling

- Store pallets flat, never on edge, to prevent warping and moisture retention

- Use racks or supports to prevent direct contact with concrete floors

- Limit stack height to preserve airflow and stability

- Stack pallets of the same size and type together to ensure uniform drying

Maximize Air Circulation

- Maintain spacing between pallet stacks to allow airflow

- Orient pallet openings to encourage natural ventilation

- Use fans or mechanical ventilation to keep air moving; even low airflow can significantly reduce mold risk

- Remove stretch wrap and non-breathable materials immediately upon receipt

Pressure Washing and Pallet Mold Removal

- Pressure washing removes surface spores, but must always be followed by thorough drying

- According to Virginia Tech, mold cannot survive once wood moisture content is reduced below 19%, making drying the most critical step in remediation

- Chemical cleaners, including diluted bleach solutions, may kill surface mold but are not permanent solutions

- Chemical treatments may be restricted or prohibited in food, pharmaceutical, and regulated supply chains

Mold-Resistant Coatings

In high-humidity environments or long-term storage situations, mold-inhibiting coatings can be applied as an added layer of protection. These treatments help slow mold growth and provide extra assurance for sensitive supply chains.

Customer-Level Mold Prevention

Once pallets leave our facility, proper handling and storage on the customer side are just as important. Even well-manufactured pallets can develop mold if exposed to moisture or poor storage conditions.

Inspect Pallets Upon Arrival

Visual inspection upon delivery is a critical first step. Checking for signs of dampness, discoloration, or visible mold allows compromised pallets to be isolated before entering circulation.

Store in Dry, Covered Areas

Indoor storage with good airflow is ideal. Pallets should be kept away from open doors, roof leaks, and condensation-prone areas. If outdoor storage is unavoidable, pallets should be covered and placed on concrete pads or raised platforms; never directly on the ground.

Rotate Pallet Inventory (FIFO)

A first-in, first-out inventory system ensures pallets are used in a timely manner. This minimizes prolonged exposure to fluctuating humidity and temperature changes that can encourage mold growth.

Avoid Direct Ground Contact

Ground moisture is one of the most common contributors to pallet mold. Elevating pallets using racks, beams, or spacers helps prevent moisture absorption, especially during wet or snowy conditions.

Clean and Dry Recycled Pallets

Recycled pallets offer sustainability benefits but require extra attention. Prior exposure and aging wood make them more susceptible to mold, so thorough inspection and proper drying are essential before reuse.

A Shared Commitment to Mold-Free Pallets

Mold prevention is not a one-time solution; it is an ongoing process that requires attention at every stage of a pallet’s lifecycle. From heat treatment and controlled storage at the manufacturing level to responsible handling and rotation at the customer level, each step plays a vital role in maintaining pallet quality.

When manufacturers and customers work together, the results are clear: longer pallet life, fewer disruptions, improved compliance, and greater confidence in product safety. Mold-free pallets do not just protect your shipments; they reinforce your commitment to quality, cleanliness, and operational excellence.

Ready to ensure your pallet supply is clean, safe, and mold-free?

Request a Quote today and discover how Performance Pallet can support a stronger, more reliable supply chain. Or call our pallet manufacturing company at (920) 833-7839 nd speak to a live agent.

FAQs About Mold on Pallets

What causes mold to grow on wood pallets?

Mold forms when wood is exposed to excess moisture combined with warm temperatures and limited airflow. Rain, humidity, condensation, and ground contact are the most common contributors.

Are recycled pallets more likely to develop mold?

Recycled pallets can be more susceptible due to prior exposure and older wood, but proper inspection, storage, and handling significantly reduce the risk.

How does mold affect pallet recycling?

Mold limits pallet reuse by contaminating clean inventory and spreading spores within storage facilities. Pallets not remediated quickly may lose reuse value and require material recovery instead.

Is mold on pallets dangerous?

While not always harmful, mold can contaminate products, trigger allergic reactions, and create compliance issues, especially in food, beverage, and pharmaceutical supply chains.

Can mold be prevented entirely?

While no wood product is completely immune, mold risk can be minimized through proper treatment, airflow, storage practices, and routine inspections throughout the pallet lifecycle.

What should I do if I find mold on pallets?

Remove affected pallets from circulation immediately. Contact your pallet provider to determine whether the pallets can be treated, repaired, or replaced.